Hendrickson — Haulmaax

Description

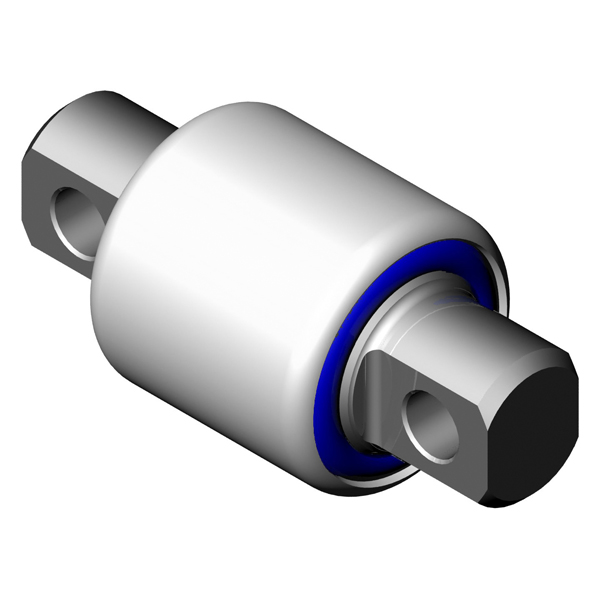

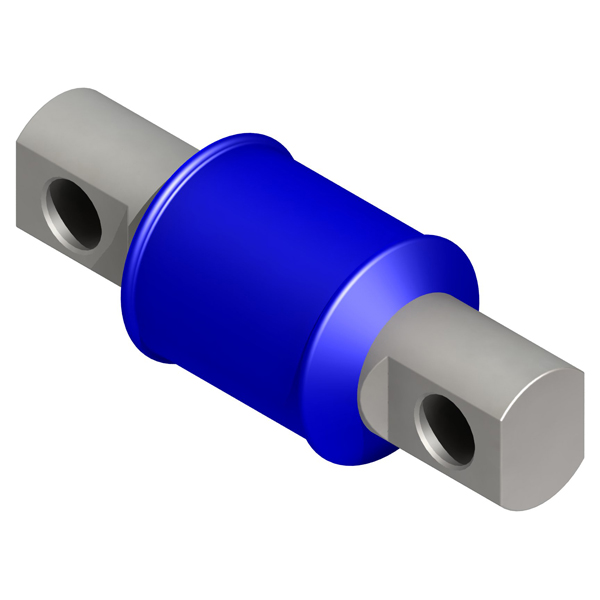

This walking beam suspension is similar in design to the Hendrickson HN suspension. It features bar pin end bushings but there are no center bushings for the beams to pivot on. Like the HN, the traditional center bushing is replaced by 4 narrow bolster springs (8 per vehicle.) The center of gravity has been lowered by designing the narrow bolster to straddle the beam in pairs compared to the HN where large single bolsters are mounted atop the walking beam.

Fast Facts

| Hendrickson — Haulmaax | |

|---|---|

| Type | Walking beam suspension |

| Features | |

| Problem Areas | |

| ATRO Solutions | |

Tech Tips and Additional Resources

Kits:

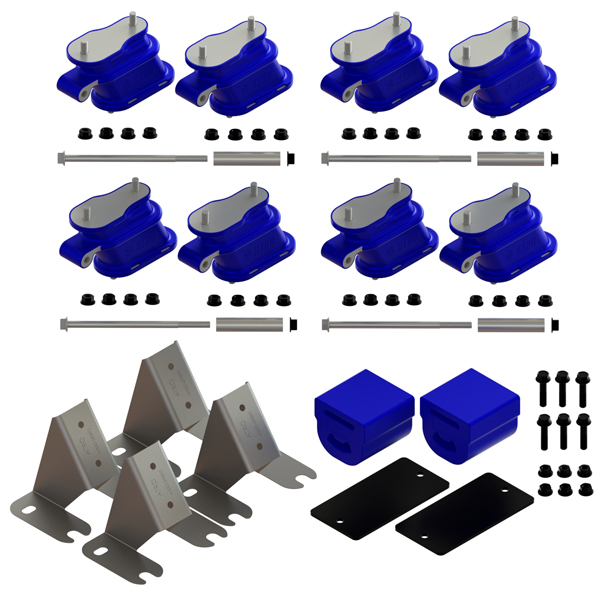

A key element in an efficient repair is having all the key parts and components. The KT50-25002 or KT50-25003 are complete kits with hardware for bolster spring repairs. The EB50-21013, bar pin in-bushing kit, contains all the necessary bolts, nuts, shim and washers. Look for detailed installation instructions by searching for EB50-21013.

- KT50-25002

- KT50-25003 (includes wear plates)

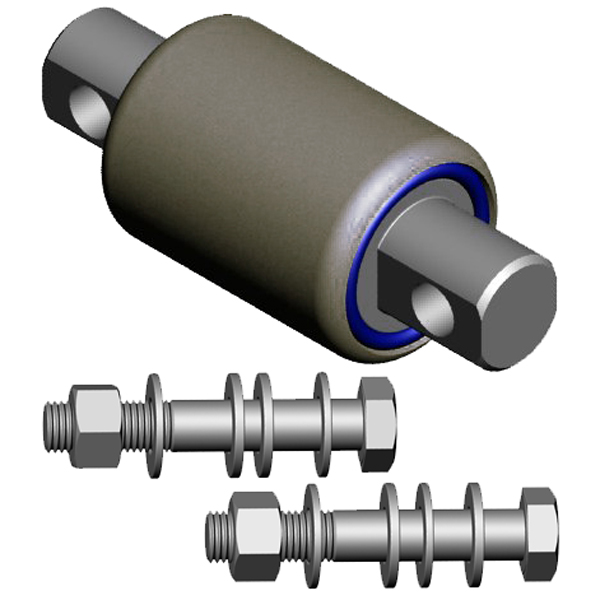

- EB50-21013

ATRO’s polyurethane material in the bolster springs and progressive auxiliary spring is impervious to chemical attack.

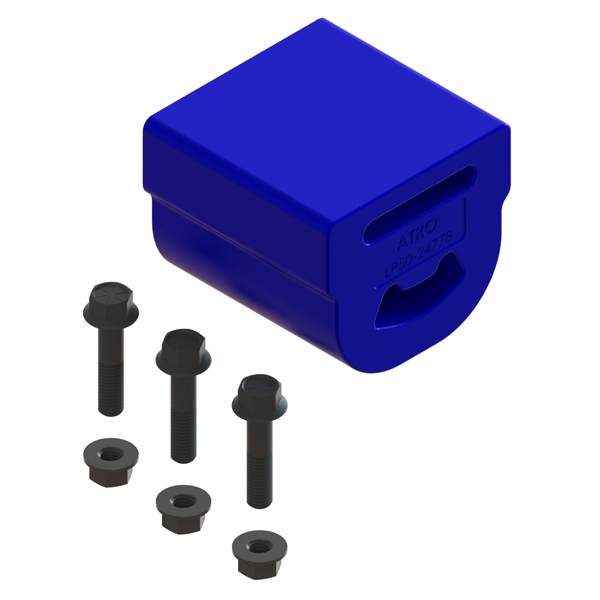

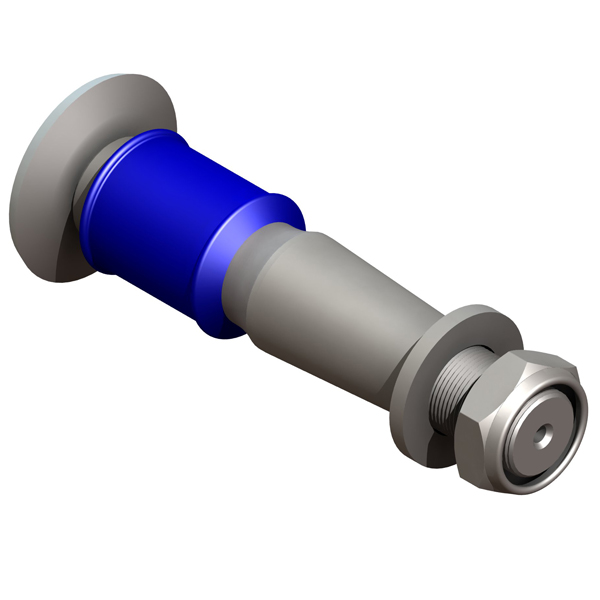

The new style LP50-24778, Progressive Auxiliary Spring, replaced the smaller old style auxiliary spring, LP50-24974, in 2014. It is important to replace the old style with the new style on both sides of the truck. To install the new style progressive auxiliary spring it may be necessary to remove shim and/or raise the frame.

- Load spring is not an overload spring or a bump stop and it is designed to carry up to 40% of the load

- Properly installed it is in contact with the contact plate on the saddle 100% of the time

Wear Items

- Transverse rods are critical, especially in high center of gravity applications like dump trucks and concrete mixers. Check periodically for wear

-

Check bolsters for cracks/debonds

- Replace if material is cut 1" length or 3/8" in depth

- Replace if bond separation is >1/2" deep

The most common root causes of cracked or broken frame brackets:

- Vehicle is overloaded

- Worn transverse torque rods

- Frame bracket bolts/fasteners are loose

- Auxiliary spring is worn

Failure Analysis:

A debond of a bolster spring may be a secondary failure and the location of a debond can help locate the source of the root cause.

| Location | Possible Primary Failure Point |

|---|---|

| Debond at top plate | Check torque rods for bushing failure |

| Debond at lower plate | Check bar pin end bushing for failure |

Key Parts

Torque Rods are availble in any length, or as two-piece rods.

Details

Hendrickson Haulmaax

Properly outfitted Haulmaax suspension with engaged progressive load spring.

Hendrickson Haulmaax

Worn auxillary spring, ATRO MS50-29791 Shim Plates.